Built to Order

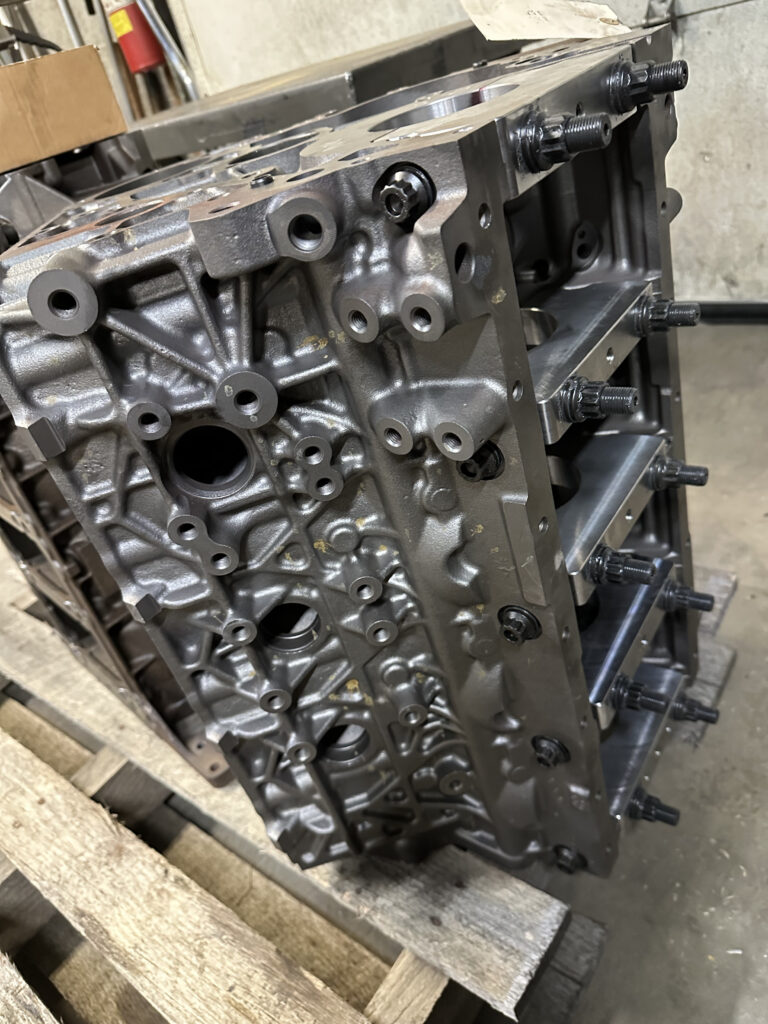

It all starts with a solid foundation.

After setting a plan in place for your build specs & power goals.

We can begin the engine building process.

Dis-assemble engines clean & inspect all parts

Covers are vaper cleaned

All blocks go through a thorough inspection bake & blasting, followed by crack detection

If all is good, the block will be prepared for the machining process.

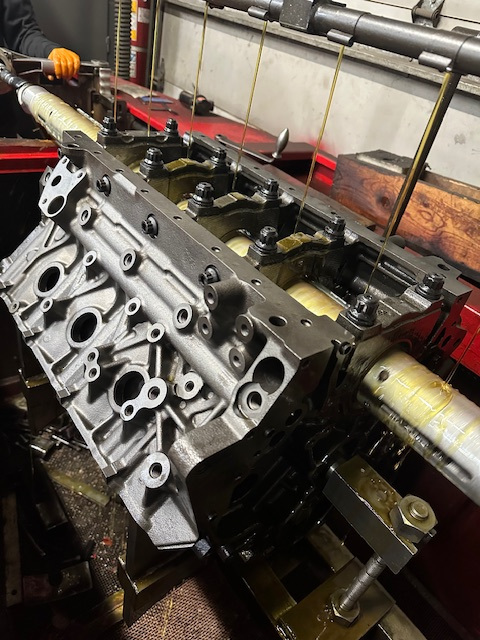

Blocks will then be Line Honed to set proper clearances on the main caps. The crankshaft sits in the main journals, so they’ve got to be dead-on straight. Align honing trues them up, keeping the crank spinning smooth under load. A Duramax needs this for towing tons, while race engines demand it to survive High RPM abuse.

Next up, the cylinders get bored out. This isn’t just drilling holes—it’s about precision. A CNC machine or boring bar enlarges the cylinders to accommodate oversized pistons, ensuring exact tolerances.

The block’s top surface (the deck) gets milled flat. This ensures a perfect seal with the head gasket.

Some blocks depending on build can go through some custom machining,

Such as lifter bushings, oversized cam bearings, roller bearings & billet main caps

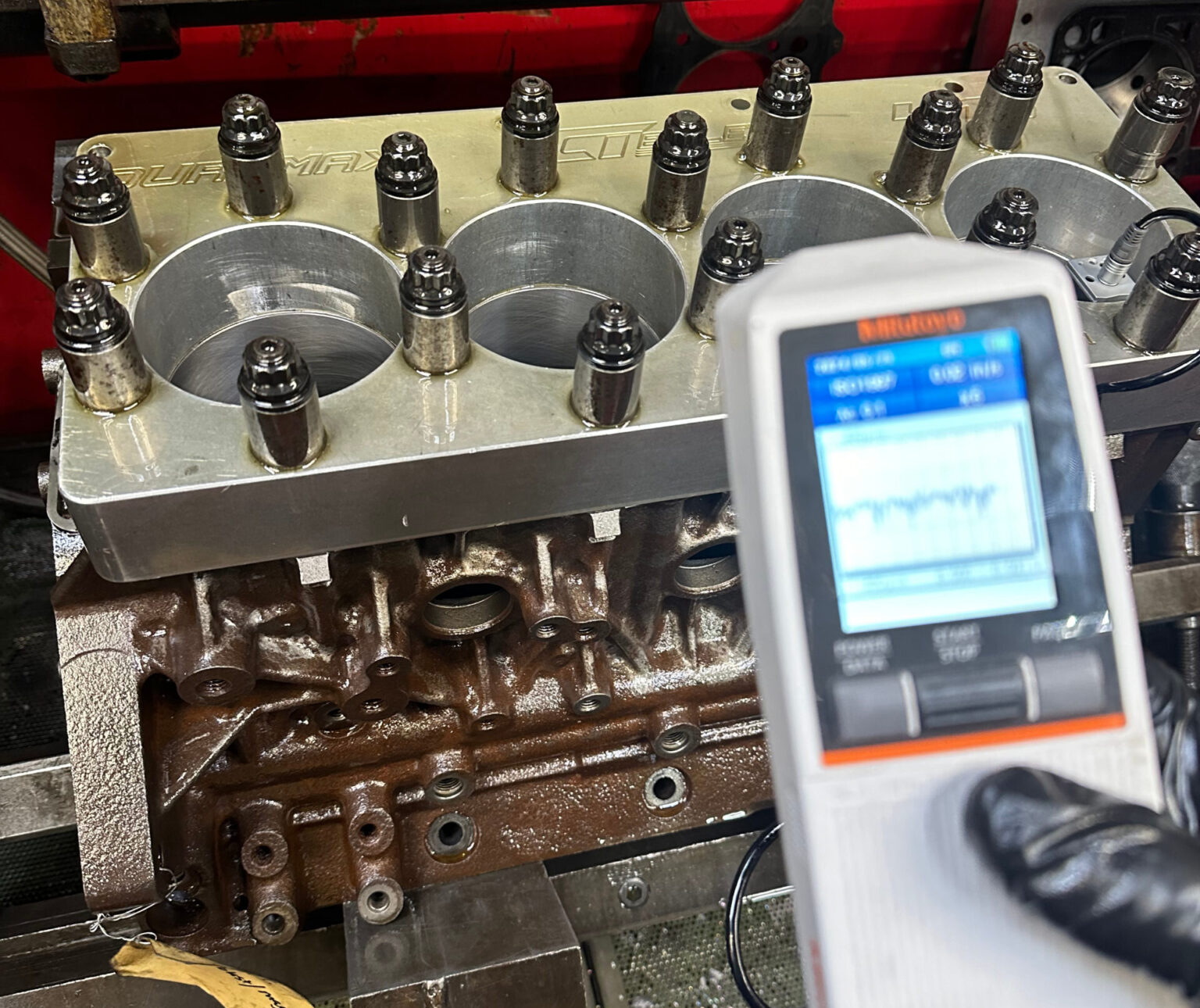

After boring, the cylinders are rough. Honing smooths them out, creating a crosshatch pattern that holds oil and seats the piston rings just right. Setting up Surface finish to the application of the engine.

Next Crankshaft, rods, and pistons get weighed and balanced. For a Duramax, this cuts vibration under heavy loads. In race engines, it’s about hitting 10,000 RPM

The cylinder heads get their turn— Duramax heads might get beefier seats for diesel punishment, while race heads chase airflow with porting and polishing for every last horsepower.

Cylinder heads are pressure tested and checked.

We then vaper clean the heads to make it look new.

Replace valve guides and reface or install new valves.

We check valve springs and set up pressure for given application.

Heads are valve jobbed then resurfaced, final cleaned and assembled.

Everything gets a deep clean—debris is the enemy of a fresh engine. Threads are chased, surfaces checked, and After that, engine is ready for final assembly.

For Duramax engines, machining prioritizes strength. Race engines? It’s all-out performance, tighter clearances, and exotic materials to shave weight and boost power. Either way, the process turns a chunk of metal into a masterpiece.